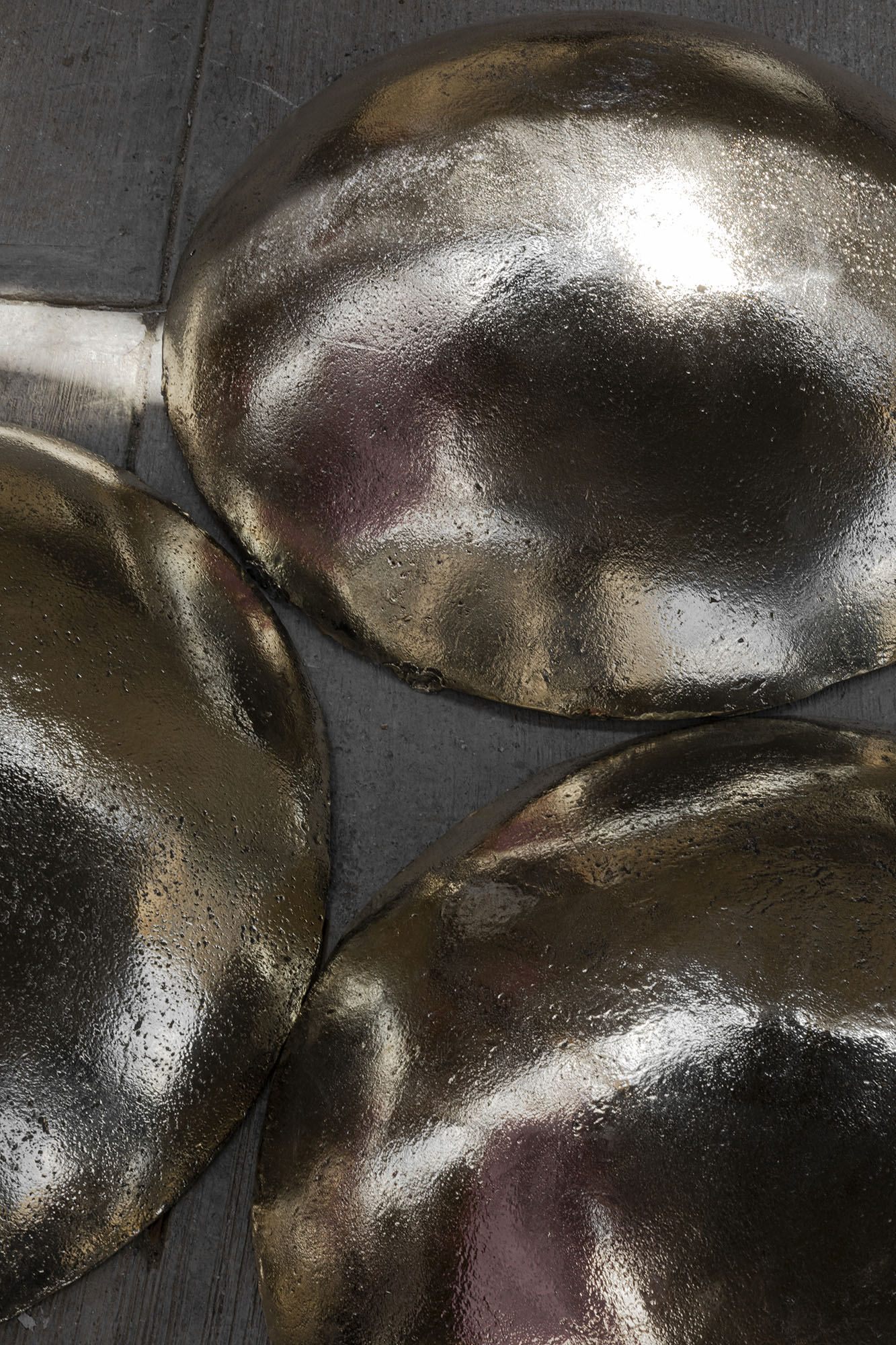

The Copal Coffee Table draws inspiration from ritual elements rooted in Mexico, specifically the “copaleras”, objects similar to censers or cauldrons used for burning copal, a tree resin said to facilitate communication between humans and deities. Enveloped in an aura of mysticism, the Copal appears to float in the air, defying gravity through its cantilever design. Crafted with precision, the table is made of six half spheres, skillfully assembled to create a visually challenging piece. Its hidden elements and tangential connection contribute to the piece’s balance and structural integrity.

SINCRETISMO

2022

SAND CASTED

POLISHED BRONZE

L59 x W55 x H12 in

L150 x W140 x H30 cm

LIMITED EDITION OF 5 + 2 AP

The table’s hidden elements and the tangential connection of its parts contribute to the piece’s balance and the structural integrity of the whole. Its composition results in a piece that has perfect equilibrium. This construction technique gives the impression that three out of the four parts delicately touch and hover in the air.

The Copal Coffee Table in Polished Bronze at ‘Harmonious Contradiction’, Masa Galería x Sotheby’s collaborative exhibition in East Hampton, 2022.

The Copal Coffee Table is fashioned from six semi-spheres carved out of local volcanic stone, a material sourced from a quarry near Mexico City and renowned for its distinct porosity. The process further involves crafting molds using fiberglass and silicone for the six volcanic stone hemispheres. Subsequently, wax replicas are meticulously produced to mirror every detail, including pores, cracks, and unique features that distinguish each sphere.

These delicate wax reproductions are then enclosed in a specialized sand and subjected to approximately 2.5 days of heating. This stage aims to systematically eliminate the wax figure, leaving behind its negative space within dehydrated sand. The molten bronze is subsequently poured at temperatures ranging between 900 – 950 °C (1652 – 1742 °F), and after around half a day, the resulting replicas are allowed to cool.

The sand mold is destroyed to extract the component and proceed to clean it off burrs and any other extra material. Once all the components of the table have been melted, the assembly process begins, this is a neuralgic step to achieve the visual tension and functionality representative of this work. Due to the craftsmanship, each piece contains different details and irregularities, which EWE does not perceive as an error, on the contrary, it aims to preserve and embrace it, making each piece by the studio unique.

The sand mold is dismantled to extract the component, and subsequent steps involve removing any burrs or excess material. Once all the table components have undergone the melting process, the assembly phase commences—a critical step in achieving the visual tension and representative functionality of this work. Due to the artisanal craftsmanship involved, each piece harbors distinct details and irregularities. EWE does not view these variations as errors; instead, the studio strives to preserve and embrace them, rendering each piece unique.